Your shopping cart doesn't have any products yet!

Technical Specifications

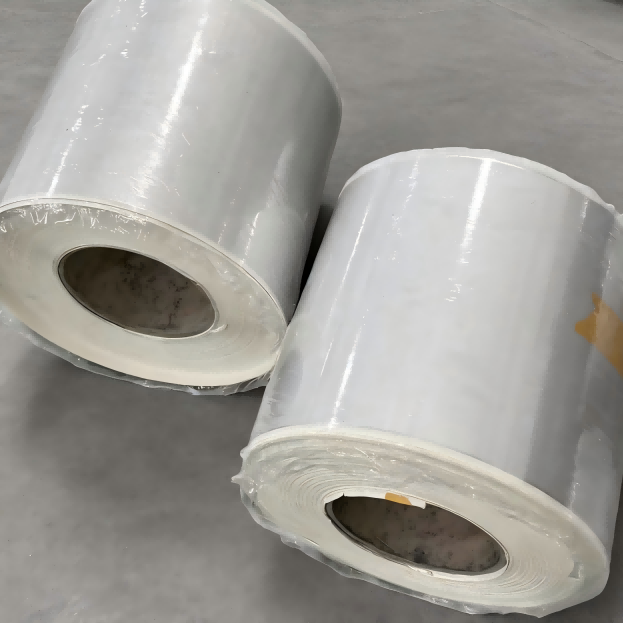

Aluminum foil thickness: 12–20 microns (0.012–0.02 mm)

PE/PET seal layer thickness: 15–30 microns (0.015–0.03 mm)

Total liner thickness: 0.2 mm – 2 mm (customizable)

Available thickness options: 0.6 mm and 1.5 mm

Seal diameters: 10 mm – 180 mm

Seal backing materials: plastic, foam, cardboard

Types: easy peel / non-easy peel

Customization: OEM logo printing or embossing available

Materials Available: XPET, OHPE, PE, CPP, PVC, PS, XBL (for honey packaging), BL (for glass bottle sealing), pressure-sensitive liners, easy-tear liners, composite aluminum foil foam type, non-separating liners, customized designs.

Key Features

High barrier protection against oxygen, moisture, and leaks

Composite foil + paper structure for stronger sealing

Compatible with heat induction sealing technology

Maintains freshness, prevents contamination

Eco-friendly, safe, and customizable

Applications in Packaging

Pharmaceutical bottles: tablets, capsules, powders, syrups, and liquids

Food bottles: honey, milk, oils, sauces, condiments

Cosmetic and chemical containers: creams, serums, cleaning agents

This seal liner enhances packaging integrity, prevents tampering, and improves consumer confidence.

Why Choose Us?

We use advanced production technology and strict quality control to produce reliable, customizable, and eco-friendly aluminum foil paper seal films. Our solutions help customers achieve airtight, tamper-proof, and sustainable packaging for food and medicine industries.