Your shopping cart doesn't have any products yet!

Key Features

Hydrophobic Protection: Repels water, ensuring packaging remains dry and safe.

Solvent Resistance: Protects against organic solvents, chemicals, and oils.

Breathability & Pressure Balance: Allows controlled airflow to prevent packaging deformation.

Contamination Barrier: Blocks dust, particles, and microbes from entering.

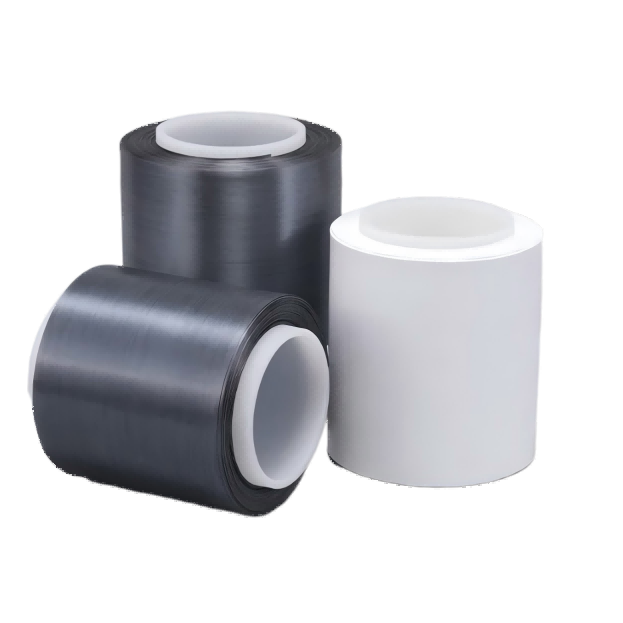

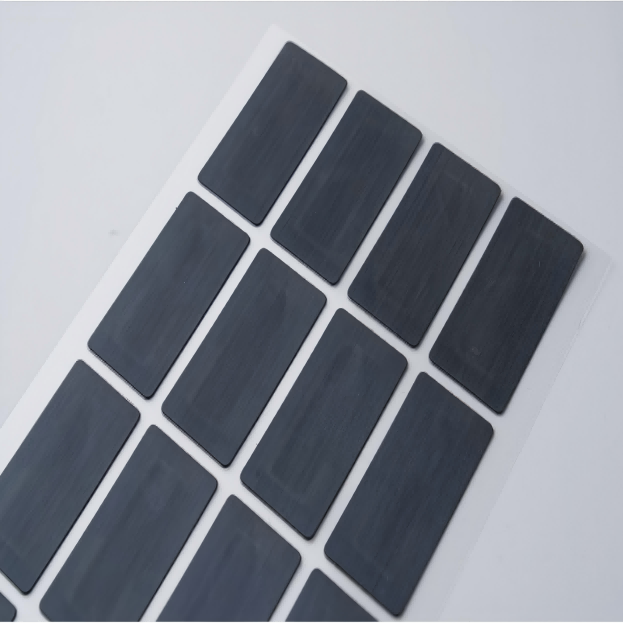

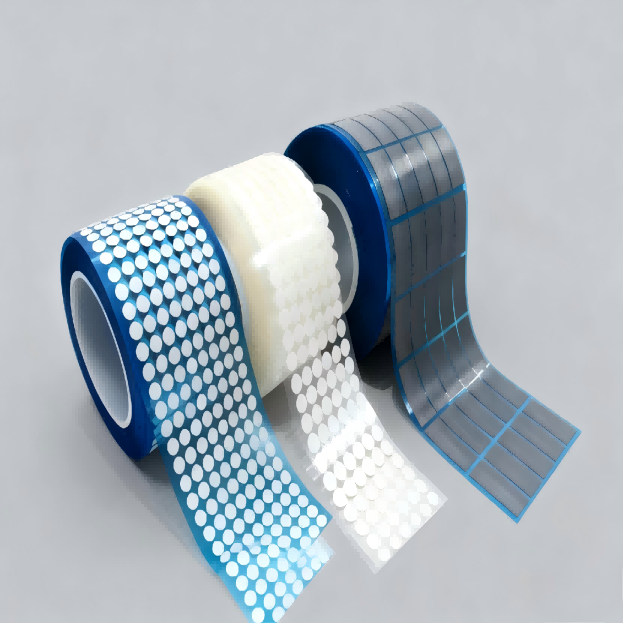

Customizable Solutions: Available in multiple pore sizes, thicknesses, and roll/sheet formats.

Applications

Food Packaging: Prevents deformation caused by trapped air or gas during shipping.

Pharmaceutical Packaging: Protects sensitive drugs by balancing pressure while preventing moisture ingress.

Cosmetics & Personal Care: Ensures safe packaging of lotions, oils, and solvents without leakage.

Chemical Packaging: Suitable for aggressive solvents and industrial products requiring breathable yet sealed protection.

Technical Specifications (Example)

Material: 100% PTFE

Surface: Hydrophobic treated

Pore Size: 0.1–5 μm (customizable)

Thickness: 20–150 μm

Airflow: Adjustable per application

Temperature Resistance: -40°C to +260°C

Why Choose Our PTFE Filter Membrane for Packaging?

Effectively prevents packaging bulging, rupture, and leakage

Superior resistance to solvents and moisture

Stable performance with consistent quality control

OEM/ODM customization for different packaging formats

Widely applied in food, pharma, cosmetics, and chemical industries

FAQ

Q1: Why use hydrophobic PTFE membranes in packaging?

A1: They provide waterproof and breathable protection, balancing internal and external pressure while blocking contaminants.

Q2: Can these membranes handle organic solvents?

A2: Yes, PTFE membranes are naturally resistant to organic solvents, oils, and chemicals, making them ideal for chemical and cosmetic packaging.

Q3: Will using these membranes affect package sealing?

A3: No, the membranes maintain sealing integrity while allowing controlled airflow to prevent deformation.

Q4: Are customized designs available for packaging?

A4: Yes, we offer tailored sizes, pore structures, and performance options for different packaging requirements.