Your shopping cart doesn't have any products yet!

1. Product Overview

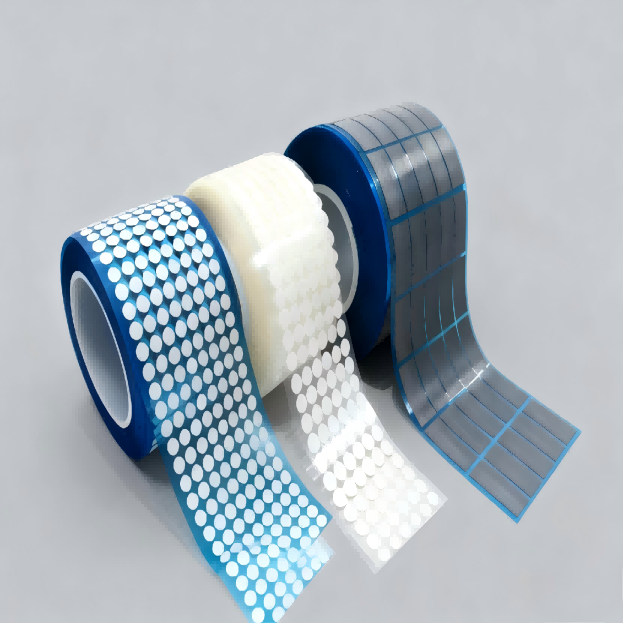

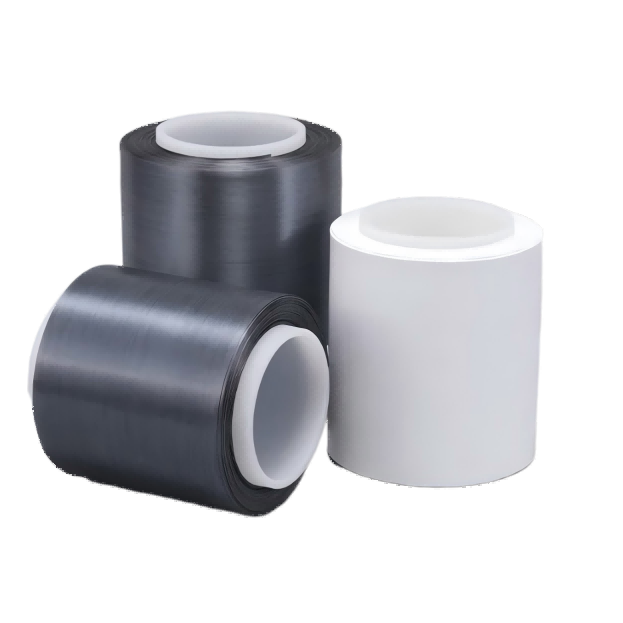

The Weldable Breathable Membrane represents a significant advancement in bottled product packaging technology, combining robust sealing capabilities with precise ventilation control through innovative heat-welding compatibility. This specialized membrane is engineered to create permanent, leak-proof seals on various plastic containers while maintaining essential breathability to prevent pressure buildup and ensure product stability. The membrane's unique composite structure allows it to bond securely with container materials during thermal welding processes, forming an integral part of the packaging that cannot be compromised or dislodged during handling and transportation. This permanent integration is particularly crucial for hazardous chemical packaging, where any seal failure could have serious consequences, and for pharmaceutical products requiring absolute integrity throughout their shelf life. The microporous architecture of the membrane enables controlled gas exchange, allowing internal pressure to equalize with external atmospheric conditions while effectively blocking liquid penetration and particulate contamination. This dual functionality addresses the fundamental challenge in bottled product packaging: maintaining container integrity while managing internal pressure fluctuations caused by temperature changes, chemical reactions, or altitude variations. The welding compatibility extends across multiple container materials including HDPE, PP, and PET, making it a versatile solution for diverse packaging applications from industrial chemicals to sensitive pharmaceuticals.

2. Core Advantages

Permanent Sealing: Heat-welded bonds create irreversible, leak-proof seals

Controlled Ventilation: Precise airflow management prevents pressure issues

Chemical Compatibility: Resistant to wide range of chemicals and solvents

Strong Integration: Becomes integral part of container structure

Temperature Resilience: Maintains performance across extreme temperatures

Process Efficiency: Compatible with automated welding equipment

3. Technical Specifications

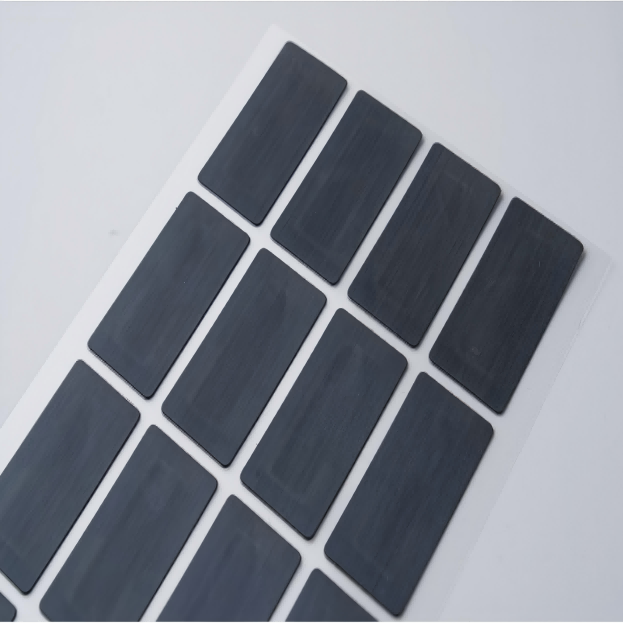

Material: Multi-layer polymer composite

Welding Temperature: 120-180°C (depending on substrate)

Airflow Rate: 50/250 ml/min·cm² (customizable)

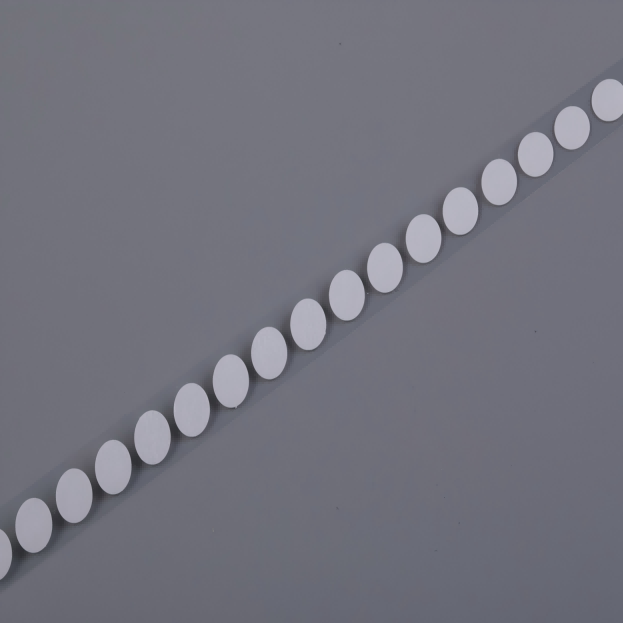

Product diameter: 5mm-30 mm (customizable)

Operating Temperature: -50°C to 150°C

Chemical Resistance: pH 1-14 (material dependent)

Thickness: 0.05-0.5 mm

Welding Methods: Thermal, ultrasonic, and laser welding compatible

4. Application Fields

Chemical Packaging: Permanent venting for hazardous chemical containers

Pharmaceuticals: Integrity-assured ventilation for medicine bottles

Automotive Fluids: Reliable venting for oil and additive containers

Industrial Chemicals: Heavy-duty ventilation for industrial containers

Agricultural Products: Durable venting for pesticide packaging

Electronic Chemicals: Precision ventilation for sensitive chemical containers