Your shopping cart doesn't have any products yet!

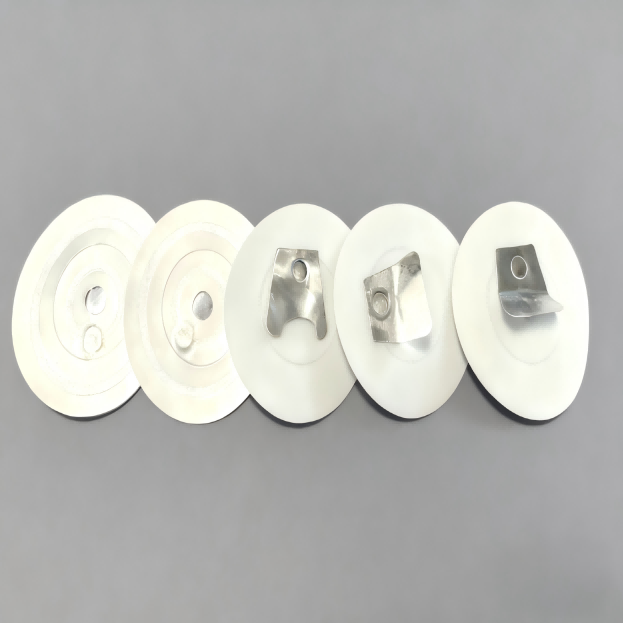

Waterproof Breathable Foam Vent Wads with Holes

Description

Waterproof Breathable Foam Vent Wads with Holes provide ideal moisture protection and controlled airflow for bottled products. Perfect for carbonated beverages, pharmaceuticals, and liquid containers. Maintains product freshness while preventing pressure buildup.

The Waterproof Breathable Foam Vent Wads with Holes is a high-performance composite sealing material that combines airtight sealing, moisture resistance, and pressure balance.

It consists of an aluminum foil layer, a PE heat seal layer, and a PTFE venting membrane.

This liner effectively prevents leakage and bottle deformation, making it ideal for gas-generating, surfactant-containing, or moisture-sensitive products such as fertilizers, pesticides, disinfectants, peroxides, additives, and essential oils.

1. Product Features

Anti-bulging and leak-proof design with automatic venting

Waterproof and breathable barrier

Excellent chemical and corrosion resistance

Compatible with PE, PET, HDPE, PP containers

Customizable structure, vent rate, and logo printing

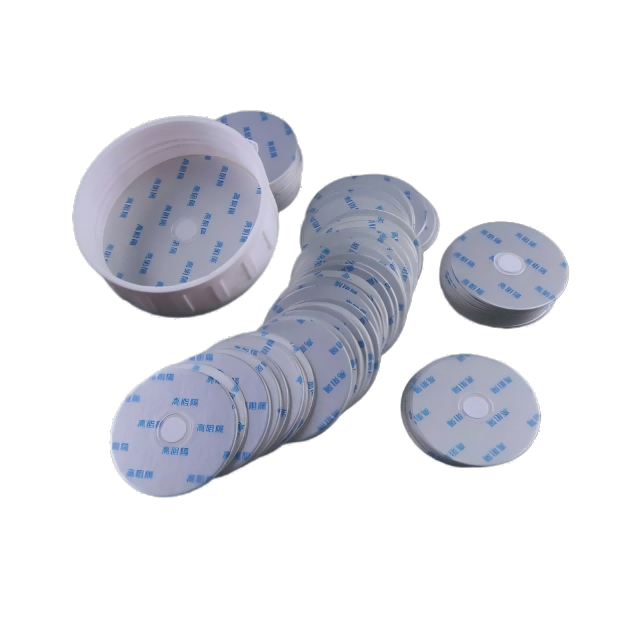

2. Technical Specifications

Material: Cross-linked polyethylene foam

Hole diameter: 1.5mm ± 0.2mm (customizable)

Hole distribution: 15-20 holes per square inch

Water resistance: IPX7 rating (submersion protection)

Air permeability: 2.5-3.5 L/min·cm²

Temperature range: -30°C to 120°C

Thickness options: 1.5mm, 2mm, 3mm

3. Application Scenarios

Safe packaging for various industries that require breathability,Widely used for packaging liquids, powders, and gas-generating materials such as:

- Fertilizers, pesticides, herbicides, fungicides

- Surfactant-containing detergents and household cleaners

- Peroxides, disinfectants, and oxidizing agents

- Flavorings, nutritional additives, and liquid supplements

- Essential oils, cosmetics, and fragrances

- Pharmaceuticals and laboratory chemicals

4. Product Advantages

Prevents leakage and deformation from internal pressure

Moisture-proof and oxygen barrier for long shelf life

Enhances packaging safety and brand reliability

Adaptable to a wide range of chemical liquids